Contact Us

![]() Home Page > Product Center > Industrial Scale Series > Electronic belt scale > ICS-17A electronic belt scale

Home Page > Product Center > Industrial Scale Series > Electronic belt scale > ICS-17A electronic belt scale

Details

The ICS-17A electronic belt scale has a dynamic cumulative error of less than ± 0.25% and is suitable for weighing process control in industrial enterprises, such as detecting production volume, controlling quantitative loading of products, and monitoring inventory. It provides important data information for factory automatic control and modern management.

System composition

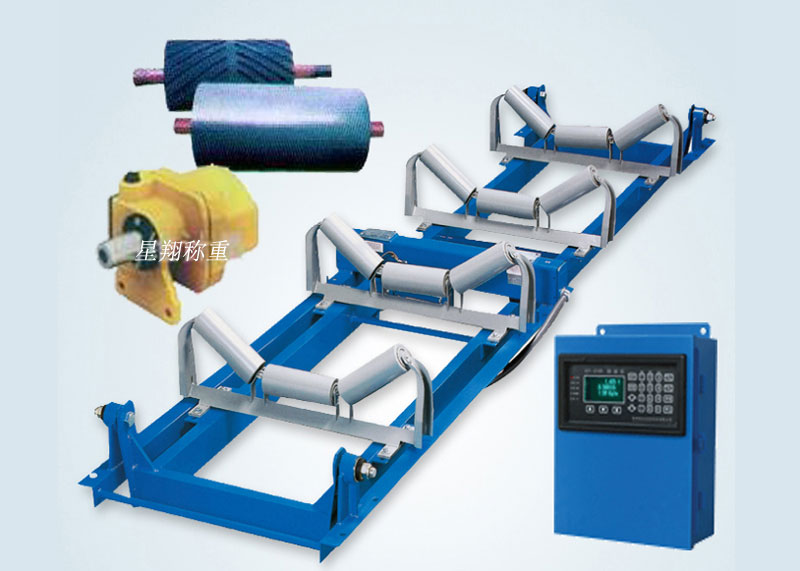

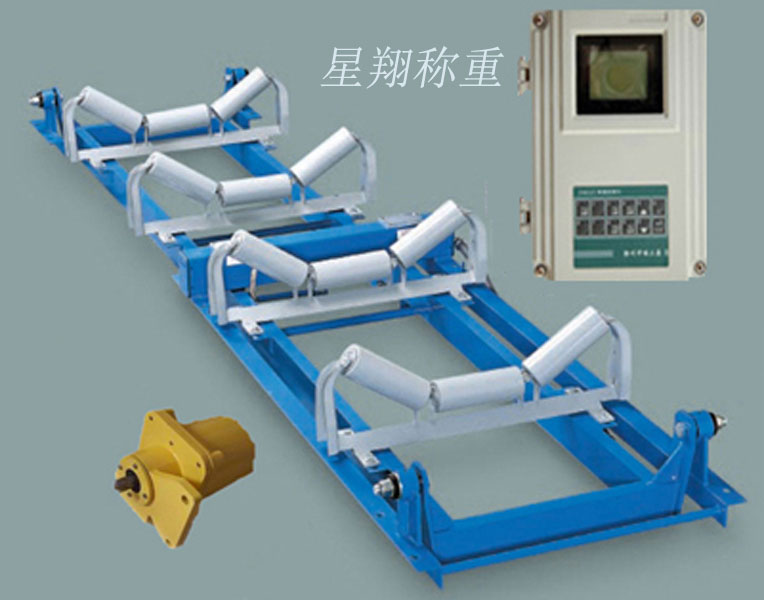

The ICS-17A electronic belt scale consists of four parts: the ICS-17A weighing bridge, weighing sensor, 60-12C speed sensor and speed roller, and SS2001 weighing controller.

Weighing bridge

The ICS-17A weighing bridge is equipped with four sets of rollers on the double bar, supported by two pull type sensors in the middle, and supported by frictionless ear pivot points on the outer side. Effectively overcoming the impact of biased loads on accuracy, this enclosed device can prevent vibration, moisture, corrosion, and material accumulation, thus avoiding the problems caused by the use of blade devices and bearing devices in harsh environments. The main beam of the weighing bridge is made of rectangular steel pipes, which gives the entire weighing bridge sufficient rigidity, small self weight, and minimal external dust accumulation area. In order to ensure the stability of the entire system, high-precision resistance strain gauge sensors are installed at the tensile position to reduce nonlinear errors.

The ICS-17A weighing bridge can be directly installed in various belt conveyor frames of different widths, located between the upper and lower belts, without occupying space height. It is an assembled whole in the factory, which can be quickly and conveniently installed and calibrated. The weighing bridge is suitable for belt widths ranging from 400-2000mm

load cell

The ICS-17A series electronic belt scales all use pull type electronic strain gauges.

The main technical indicators are as follows:

◇ Shell: "S" type sealed protection

◇ Nonlinear:<0.03% FS

◇ Non repeatability:<0.01% FS

◇ Creep:<0.02% FS

◇ Zero point output: ± 1%

At maximum flow rate, the displacement of the force application point of the sensor elastic body shall not exceed 0.2mm

◇ Temperature sensitivity: Interval: 0.0008% FS/OF

Zero point: 0.0015% FS/OF

◇ Lag error: 0.02%

Sensitivity error: ± 0.1%

◇ Overload capacity: 150% of sensor capacity

Speed sensors 60-12C, 60-12B

The speed sensor is installed on the tail drum, large-diameter drum or speed roller, and the speed roller/roller is installed on the upper surface of the return belt, eliminating the impact of belt slippage. The speed sensor is a digital brushless pulse generator. When the belt is running, the speed sensor emits a series of speed pulses, each pulse representing a unit length of the belt travel. The pulse frequency is proportional to the belt speed.

The shell material is cast aluminum, which can adapt to outdoor working environments

The communication pulse generator does not require adjustment or replacement of the carbon brush

Brushless AC pulse generator, no adjustment or calibration required, maintenance free

The latest soft connection technology ensures more effective speed measurement accuracy and greatly improves the service life of equipment

SS2001 Weighing Control Instrument

Using a 32-bit CPU and a 24 bit A/D converter, it speeds up operation and improves measurement accuracy;

All data from the belt scale is displayed on a high brightness four line vacuum fluorescent screen;

The menu style panel operation mode conforms to people's computer operation habits;

When the data related to the belt scale is changed, the original data can be retained for querying to reduce human errors;

◆ Provide multi-level password protection to facilitate different users; Provide linear compensation to ensure the same accuracy of the belt scale between 25% and 100% of the rated load;

◆ Optional analog output for displaying material flow, weight, or speed;

◆ Optional analog output delay for practical control use;

◆ Optional analog input/output board (one or two voltage and current input/output) for control or compensation purposes;

◆ Optional RS-232/RS-485 communication board, which allows you to choose one of the two modes from the hardware settings;

The 2000 series instruments include the 2001 and 2105 models for users to choose from;

主站蜘蛛池模板: 堆龙德庆县| 人人妻人人澡人人爽| 国产精品青青青高清在线| 国产AV国片精品一区二区| 国内少妇偷人精品| 噜噜噜AV久久AV苍井空| h午夜福利亚洲专区| 国产精品色内内在线播放| 免费 无码 国产在线网站| 天天爽天天爽夜夜爽毛片| 闺蜜撕开的奶罩猛吸我的奶| 青田县| 亚洲av乱码久久精品蜜桃| 久久久久久国产精品mv| 亚洲成av人片在线观看www| 久热国产VS视频在线观| 国内精品久久久久久tv| 日韩视频在线观看| 丰满老熟妇中文字幕| 日韩专区无码专区| 中文成人无字幕乱码精品区 | 国产成人亚洲欧美| 一二三四免费中文字幕| 国产黄色小视频在线观看| 欧美麻豆久久久久久中文 | 欧美亚洲另类丝袜综合网| 久久免费看少妇高潮V片特黄| 精品久久久噜噜噜久久| 国内揄拍国产精品人妻门事件| 中文字幕的av在线| 人妻精品久久久久中文字幕一冢本| 欧美一级??片内射欧美美妇| 亚洲精品视频在线观看| 日本边吃奶边摸边做在线视频 | 亚洲精品偷拍无码不卡AV| 成人精品国产区在线观看| 琪琪视频在线观看| 亚洲欧美中文字幕在线观看| 国产成人无码精品久久久APP| 欧美日韩亚洲国产一区二区三区| 亚洲中心精品国产一区|